Aerospace & Defense

Precision machining for mission-critical parts with AS9100-level quality and traceability.

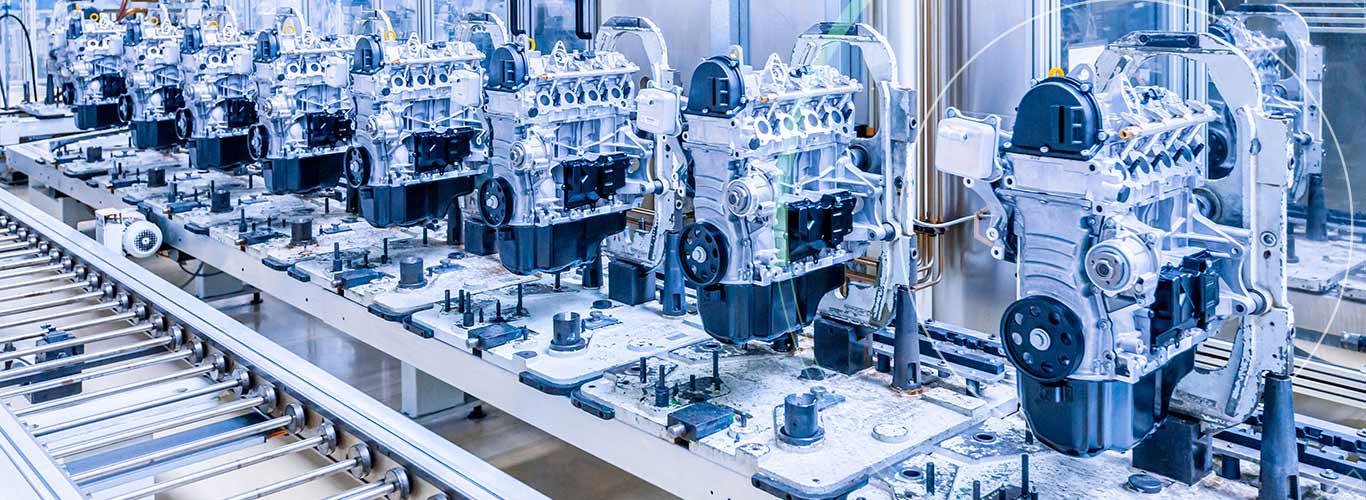

Our Capabilities

We specialize in machining precision components that meet the uncompromising standards of aerospace and defense manufacturing. With 5-axis capability, advanced CMM verification, and AS9100-aligned quality systems, we produce mission-critical parts where accuracy, consistency, and documentation are essential. From prototype to production, every part is crafted to perform flawlessly in extreme conditions.

Capabilities Include:

5-Axis CNC Machining – Complex geometries produced in a single setup for maximum accuracy.

Tight-Tolerance Turning – Precision cylindrical parts with live-tooling and sub-spindle efficiency.

Material Expertise – Aluminum, titanium, Inconel, stainless, and specialty alloys.

Metrology & Traceability – Full CMM inspection, FAIR, PPAP, and CoC documentation.

Surface & Finishing – Anodizing, chem-film, passivation, and paint through certified partners.

The Solution

Aerospace and defense programs require more than just machining capacity. They demand reliability, process control, and proof. Our team functions as an integrated manufacturing partner, ensuring every component meets strict regulatory, environmental, and dimensional standards. We provide the documentation, consistency, and speed that OEMs and Tier 1 suppliers depend on to keep aircraft, defense systems, and propulsion programs moving.

"Precision machining enables industrial companies to achieve higher accuracy, improved efficiency, and consistent quality in their manufacturing processes."

A Process That Delivers

Our aerospace machining process is built on precision, consistency, and innovation. Every operation, from programming to final inspection, is engineered to ensure repeatable accuracy and flight-grade reliability. By combining real-time data monitoring, advanced metrology, and rigorous documentation, we deliver components that meet exacting standards and exceed expectations.

The result: shorter lead times, flawless quality records, and complete confidence from the first prototype to full-rate production.

Transform Your Operation

Work with a machining partner that helps you hit your production goals and strengthen your business. Let’s move your project forward with precision and reliability.