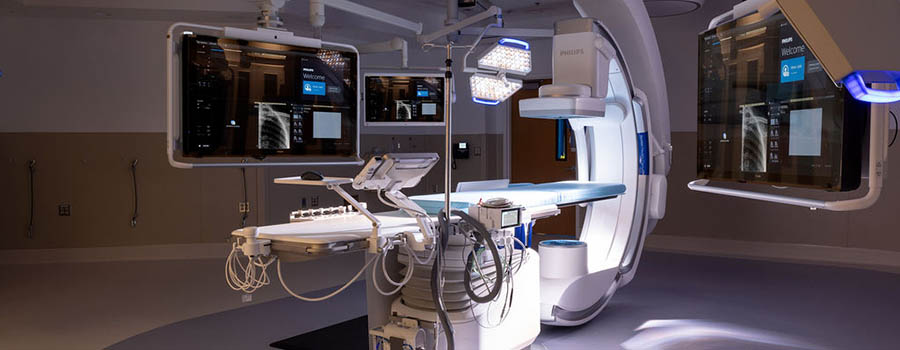

Medical

Precision machining for life-saving innovation.

Our Capabilities

We provide precision machining for medical instruments and diagnostic components that require absolute accuracy and impeccable finishes. Our state-of-the-art CNC equipment and clean manufacturing processes ensure each part adheres to the strict standards of modern medical technology. From prototype development to validated production, we operate with the precision and care essential for healthcare innovation.

Capabilities Include:

Micro & 5-Axis Machining – Ultra-precise geometries for implants and instruments.

Material Expertise – Titanium, stainless steel, PEEK, and biocompatible plastics.

Surface Perfection – Polishing, passivation, and electropolishing for smooth, contamination-free finishes.

Metrology & Verification – CMM inspection, digital traceability, and complete documentation.

Prototype to Production – Rapid turnaround for R&D and volume scaling.

The Solution

Medical manufacturing allows no room for error. Our team works closely with device engineers and quality managers to ensure every component meets regulatory and clinical standards. We provide the precision, cleanliness, and process control that enable safer products and quicker market launches.

Key Advantages:

Regulatory Alignment – Processes modeled after ISO 13485 quality standards.

Design Collaboration – Early DFM support to improve manufacturability and reduce cost.

Clean Manufacturing – Controlled environments and contamination-free workflows.

Reliable Scalability – Seamless transition from prototype to validated production lots.

"Partnering with a medical device precision machining company ensures unparalleled quality and reliability, translating to safer, more effective medical solutions."

A Process That Delivers

Our medical machining process combines innovation with repeatability. By uniting advanced metrology, clean handling practices, and precision automation, we ensure every component performs as designed—every time. The result: smoother finishes, faster validation, and complete confidence in every part delivered.

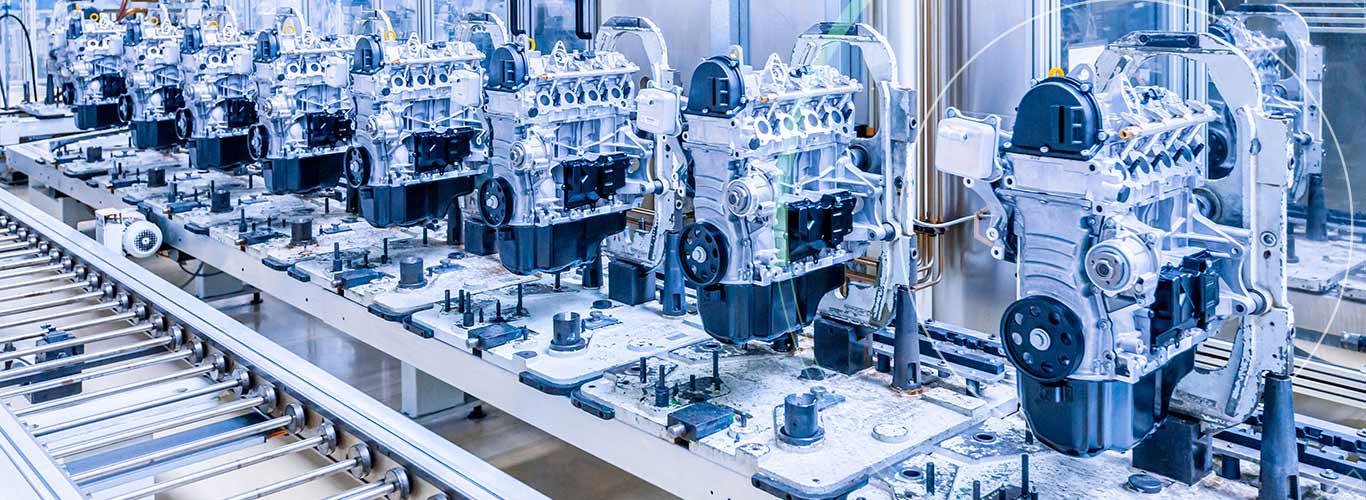

Transform Your Operation

Work with a machining partner that helps you hit your production goals and strengthen your business. Let’s move your project forward with precision and reliability.